The State of Artificial Intelligence in Manufacturing

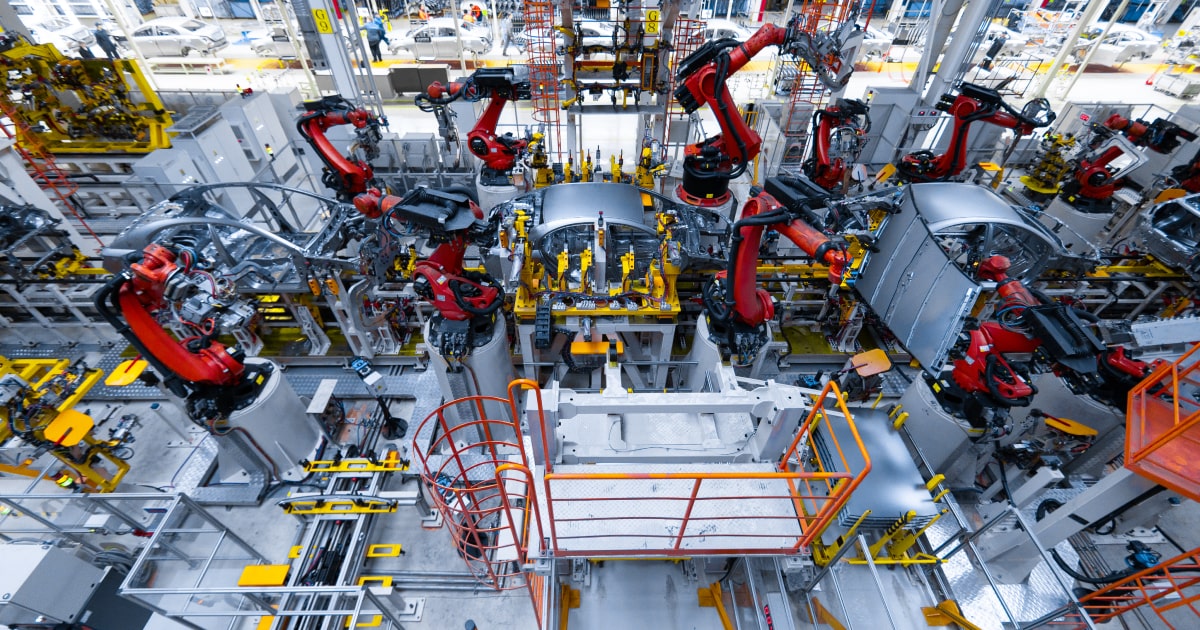

Imagine a world where machines and humans harmoniously team up on the manufacturing floor. Think of AI algorithms scrutinizing mountains of data to help manufacturers prevent breakdowns before they occur. But these are not just futuristic dreams. These are the captivating realities that AI brings to manufacturing.

A staggering 93% of companies recognize AI as the key technology for propelling growth and innovation in manufacturing. This is due to the fact that AI is already solving some of the most pressing problems that manufacturers face today: process automation, market trends prediction, improved quality inspection and product yield. The industry is banking on AI to be a game-changer.

Yet, how is AI used in manufacturing? What are the main applications of this technology in the sector? All these and other questions you might have about artificial intelligence in manufacturing will be answered throughout this article, so stay tuned.

How Does AI in Manufacturing Transform the Production?

AI in business extends its transformative potential to the manufacturing sector, optimizing processes, driving efficiency, and fostering innovation. The adoption of AI is a well-established practice among manufacturers. In fact, this trend kicked off quite a while back, in the late 1980s. Back then, artificial intelligence was empowering robotics and automation to tackle mundane, repetitive tasks such as part-handling and sorting.

But let’s skip the historical aspects and focus more on the modern-day use of AI in manufacturing. More specifically, we talk about a new era known as Industry 4.0, where automated manufacturing, supply chain, and logistics technologies are becoming more commonplace. And it’s already paying off.

AI allows us to maintain supply chains without the involvement of any physical labor. Intelligent factories can operate more effectively, endure less downtime, and improve customer satisfaction. And now that we are using the internet of things (IoT), it helps us to switch from analog to digital operations.

The Key Applications of Artificial Intelligence in Manufacturing

Just to make everything more clear, we’ve compiled a list of the key tasks and innovations enabled by AI in manufacturing industry:

- Predictive analytics

As AI solutions in industries continue to expand, the predictive power of AI remains paramount. It allows manufacturers to prevent any potential issue in the future by predicting when the operating machinery might fail and planning the necessary repairs beforehand. You can check the entire article we have on predictive maintenance, where we explain how it works.

Another way of using predictive analytics is through the software that can forecast raw material costs.

- Generative design

Industrial enterprises can make use of cloud computing and AI to generate and refine 3D models. Here, ML models are used to imitate the design process employed by engineers, enabling manufacturers to rapidly generate numerous design alternatives for a particular product.

- Quality assurance

This step is particularly critical in manufacturing, since it ensures a consistent level of quality in a service or product. By using computer vision, AI systems can quickly identify any deviations from the norm, as most defects are easily noticeable.

For instance, Foxconn, a manufacturer for major tech companies like Apple, Nintendo, Nokia, and Sony, has effectively implemented Google Cloud Visual Inspection AI to enhance quality control in its factories, reducing QA expenses.

- Process optimization

With the help of advanced analytics platforms, ML algorithms, and robotic process automation tools, organizations can enhance their processes and achieve sustainable production levels. Such AI solutions facilitate automation in IT operations, enabling organizations to automate tasks, analyze large datasets, and make data-driven decisions.

Siemens, for example, has a cognitive assistant that enables continuous, tireless monitoring of industrial installations round the clock.

Using a digital twin, one can also track and analyze the production cycle to identify potential quality issues or areas where the product’s performance may fall short of expectations. This way, AI improves the shop floor performance.

- Robotic process automation (RPA)

Manufacturing robots, commonly referred to as industrial robots, automate repetitive tasks in manufacturing and minimize or greatly reduce human errors. They redirect the focus of human workers towards more lucrative aspects of the business.

Case in point, Schneider Electric, a French multinational specializing in digital automation and energy management, implemented RPA to eliminate non-value-added tasks, saving time for employees to prioritize customer satisfaction.

- AI as a service

The concept of AI as a service is revolutionizing the manufacturing industry, allowing businesses to leverage AI capabilities on-demand. Some examples include IBM Watson AI services, Microsoft Azure AI services, Google Cloud AI Platform, and Amazon AWS AI services. They provide pre-built AI models and tools for manufacturers to integrate into their operations and gain valuable insights.

Top 5 Fields Where AI and Manufacturing Are Perfectly Synced

AI and manufacturing prove to be the perfect automation duo, don’t they? Major manufacturers today rush to adopt AI due to its potential benefits. Among the main reasons to embrace the technology in this area are:

- High revenue volatility,

- Cost-saving goals,

- Increased demand for customized/small-batch products,

- Fast manufacturing timelines,

- Production capability and supply chain complexities.

AI effortlessly addresses all of those aspects. Consequently, specific domains within manufacturing have emerged that are now wholly or partially reliant on automation. Namely:

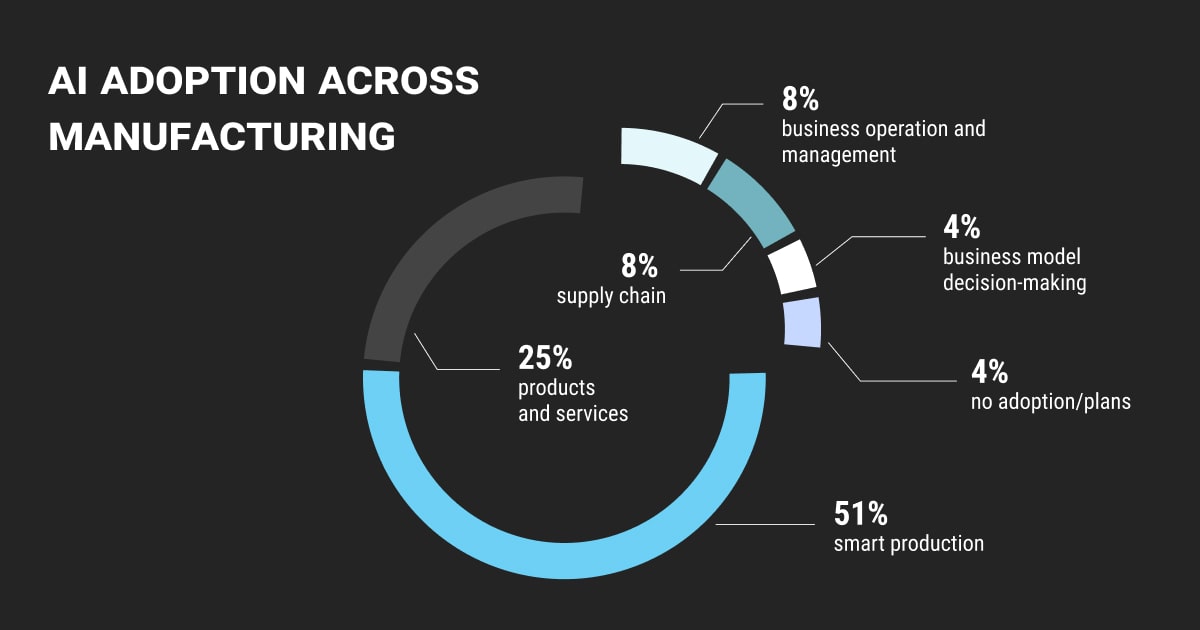

#1 Smart Production

AI is widely used in smart manufacturing for automation, order management, and scheduling, where robotic integration is key. Robotic systems can perceive changes in industrial manufacturing environments, recognize objects, and make decisions. Besides, the use of AI in quality monitoring and defect management is growing, aided by advancements in computer vision. In automated scheduling, AI optimizes delivery time, planning, processing sequence, and material distribution. Yet, successful implementation of AI in smart production necessitates complete automation equipment, management systems, and widespread sensor utilization.

#2 Products & Services

Only a few companies have used AI in products and services, but investment in AI is growing rapidly. Particularly, in shortening design time, enhancing customer experience, and improving marketing efficiency. Manufacturers face challenges in improving product performance, reducing energy consumption, and accelerating design cycles. AI applications like generative design help expedite the design process by exploring multiple solutions. AI also holds potential in enhancing customer experience, providing customer insights, and increasing marketing efficiency.

#3 Business Operations & Management

Currently, AI adoption in business operations and management is primarily observed in finance, with anticipated growth in energy and human resource management. For manufacturing companies, energy consumption represents a substantial portion of production costs. Varied factors such as equipment, techniques, processes, product mix, and energy management influence energy usage. Employing AI for efficient diagnosis enables businesses to enhance energy savings. Successful implementations of AI here have led to significant reductions in overall energy consumption in factories, including the steel manufacturing sector.

#4 Supply Chain Management

AI is increasingly adopted in supply chains, with a focus on delivery and demand management, as well as forecasting. In the future, AI will be employed in logistics services, demand management, forecasting, and asset/equipment management. Delivery management currently dominates AI adoption, ensuring secure and efficient goods transportation. AI streamlines warehouse operations and stacking through coordinated storage and robotic systems. Furthermore, by analyzing sales data, consumer records, market trends, and social media, AI enables precise revenue estimation and product creation.

#5 Business Model Decision-Making

In manufacturing, AI is primarily employed in customer experience and cost structure decision-making. Increasingly discerning customers seek customized offerings at lower prices. Many companies intend to leverage AI for accurate customer demand forecasts, intelligent product/service development, and flexible pricing/billing models to deliver integrated and interactive customer experiences. With rising labor and resource costs, businesses are also focusing on cost structure optimization. AI can replace human labor, optimize inventory, and ensure equipment stability, reducing expenses and improving cost management.

The Big Challenge of Automated Manufacturing

A significant majority of AI projects, ranging from 60% to 80%, are encountering failure. The reason? Companies have a lack of knowledge required for adequate adoption of AI, as well as the lack of necessary resources.

Implementing AI in manufacturing offers numerous benefits, such as improved productivity, reduced error rates, enhanced decision-making, and accurate trend predictions. However, there are certain challenges:

The cost and complexity of data collection, particularly in diverse and constantly changing product lines.

The need for specialized skills and training for workers, who may experience role changes.

The perfection of AI to autonomously run an entire business may require significant time and development.

Despite the challenge, AI-powered manufacturing is thriving. We share the proof in the next section, where we take a look at the future of this forward-looking industry.

The Growing AI in Manufacturing Market: Trends and Future Outlook

Here are the important statistics we gathered regarding the impact of artificial intelligence in manufacturing industry:

AI will contribute up to $15.7 trillion to the manufacturing industry by 2025.

The global AI in manufacturing market size was USD 1.82 billion in 2019 and is projected to reach USD 9.89 billion by 2027.

The market is expected to grow at a compound annual growth rate (CAGR) of 24.2% by 2028.

Manufacturers have reported a significant 50% reduction in production time through the implementation of AI.

These statistics clearly demonstrate the advancing role of AI in the manufacturing market. But before considering the adoption of smart technologies in your manufacturing business, you need to find a reliable data labeling partner to fulfill your AI development needs.

Don’t waste your time looking for one, the Label Your Data team has got you covered! You can send your request here.

The Takeaway on AI-Powered Manufacturing

AI manufacturing has revamped every aspect of the industry, from large-scale production lines to the intricate assembly of components. And now, we see increased efficiency, innovation, and remarkable profitability that are helping manufacturers reach new heights.

By integrating artificial intelligence in manufacturing, today’s factories can already:

- Detect defects,

- Reduce downtime with predictive maintenance,

- Respond to real-time demand changes,

- Ensure flawless production,

- Customize products at lower costs, and

- Automate mundane tasks.

For any industry you aim to conquer, Label Your Data provides professionally annotated datasets to bring your AI projects to life. Send your data to us and see what we have to offer.

FAQ

What companies use artificial intelligence for manufacturing?

Siemens, IBM, Intel Corporation, Rockwell Automation, GE, Mythic, NVIDIA, Uptake, Veo Robotics, Automation Anywhere, and Machina Labs, Inc. are among the top companies utilizing AI in manufacturing.

Is AI the future of manufacturing?

Yes, AI in the manufacturing industry is considered the future of manufacturing as it is beneficial in collecting and analyzing big data, enabling manufacturers to make more informed decisions and optimize their operations. AI is widely employed in various production applications, including machinery inspection, cybersecurity, quality control, and predictive analytics.

When was AI used in manufacturing?

Artificial intelligence in the manufacturing industry has been used for several years, with its implementation becoming more prevalent in recent times due to advancements in technology and its potential to optimize processes and improve productivity.

Written by

Karyna is the CEO of Label Your Data, a company specializing in data labeling solutions for machine learning projects. With a strong background in machine learning, she frequently collaborates with editors to share her expertise through articles, whitepapers, and presentations.